"Just make more"

The choctop shift can be tranquil, humbling, and quietly frustrating.

Image Credit: Patrick McKenzie

In my six years working at a cinema, I’ve learned that patrons get more upset when we’re out of choctops than when we’re out of movie tickets.

While the latter is quite a rare occurrence, a choctop famine is a near-weekly phenomenon. For the uninitiated, a choctop is your typical ice cream cone dipped in melted chocolate, which then hardens when placed in a freezer, forming a solid outer shell.

When it comes to negotiating a paucity of choctops, the exchange is always the same:

A customer approaches the counter to enquire about the availability of our finest frozen dairy treats, at which point we have to tell them we’ve run out.

“None left?” they ask.

“None left.” I answer.

“What happened?” they beg.

“They sold out.” I reply.

“You should buy more next time” they suggest.

“We make them ourselves.” I justify.

“Well then just make more.” they beseech.

Supply, demand, overhead, wage costs, profit margins, and the dying cinema industry aside, at work our managers encourage us to make them whenever we have downtime. However, the shifts dedicated solely to choctop production are a sacred undertaking by which many live, die, or are fast tracked to repetitive strain injury (RSI).

“Time passes different, it’s easy money. Get some Voltaren Emulgel on hand” my coworker Jim, a relatively new initiate behind the freezer, tells me on the eve of his next choctop shift.

I cast my mind back to a conversation from two weeks prior, where he boasted of a new record: 138 in five hours, about one choctop scooped, set, dipped, hardened, bagged, and tagged every two minutes.

The typical choctop shift begins with a trip to the basement stockroom to retrieve four to eight five-litre tubs of assorted flavours, two to four unmarked buckets of liquid dark chocolate, and a box of 288 ‘flat top sugar cones’. The rest of your shift is spent in the upstairs back-of-house area, as a sacrosanct fixture leant over two Peter’s freezers, the hustle and bustle of popcorn, drinks, and “Sorry, we only have seats left in the front row” occurring around you.

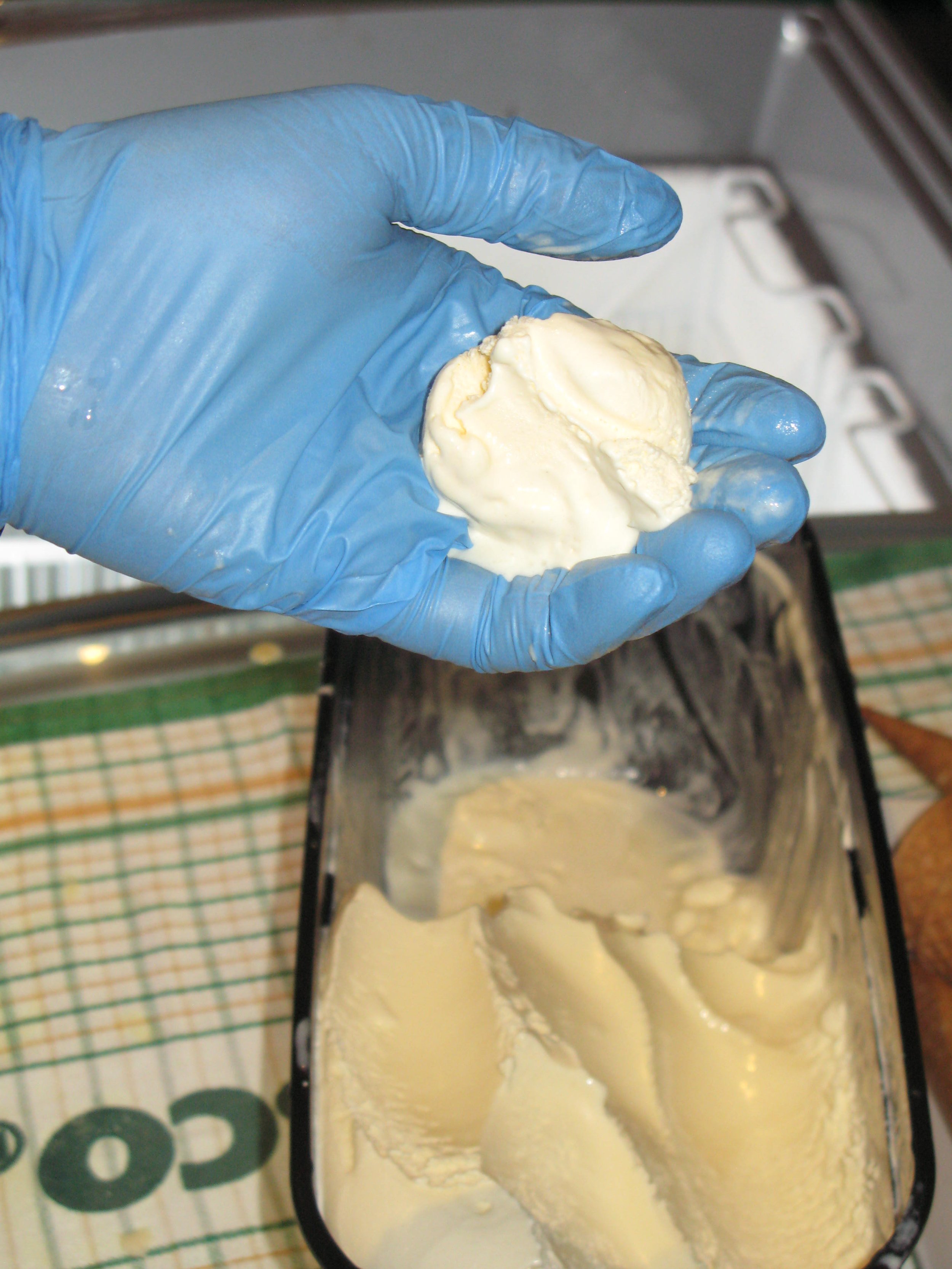

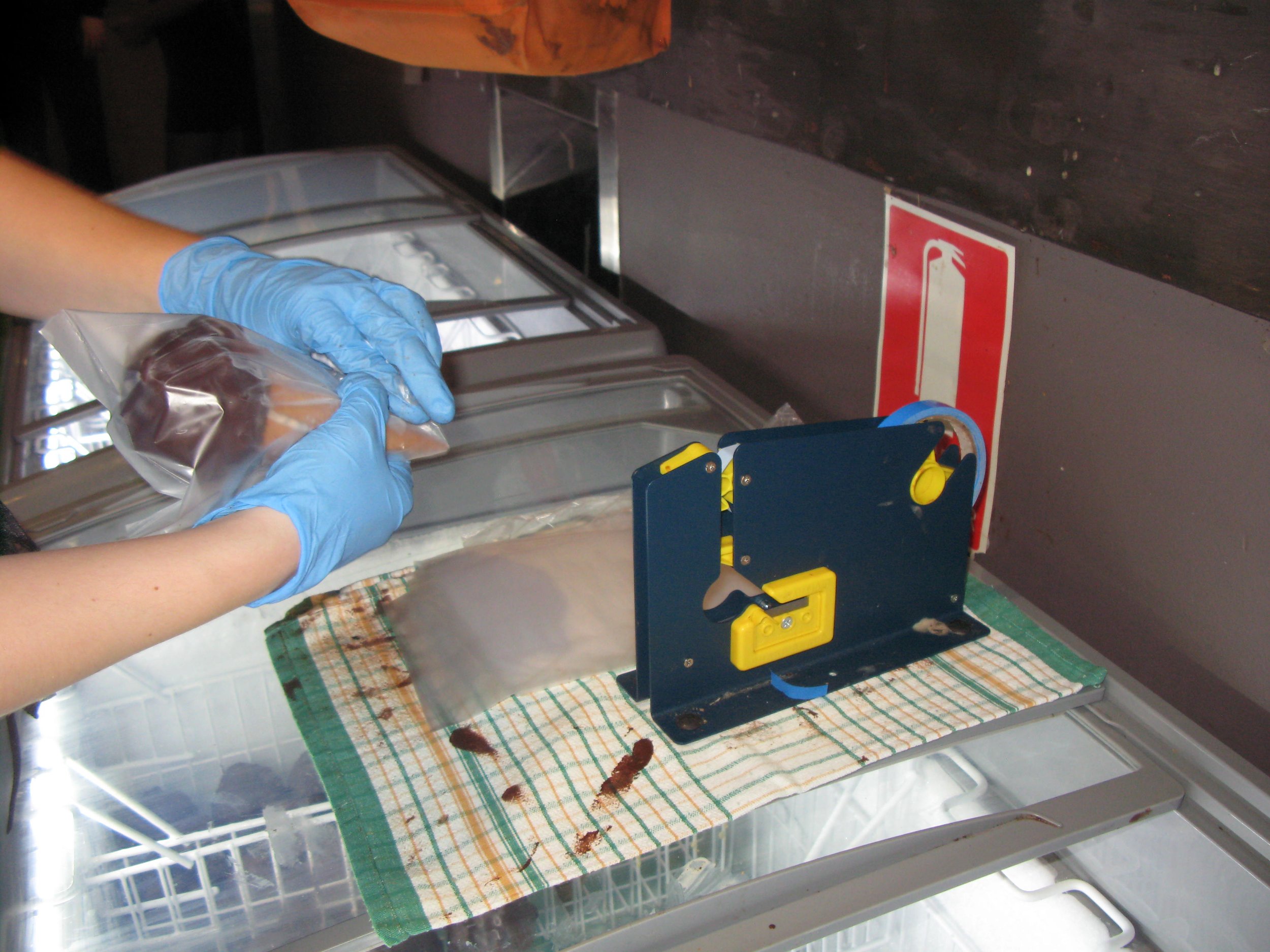

Two or three small scoops of ice cream to each cone — careful not to drop it or accidentally fling it across the room — placed in the freezer for 10 or 15 minutes to set. Dip the cones in a bucket or container of liquid chocolate and place back in the freezer to set again. Finally, place the ‘chocced’ cone in a specially made plastic choctop bag and seal it with a short length of coloured tape corresponding to the flavour.

“Hundreds of scoops and cones stacked in an interlocking zigzag formation, covered in chocolate and resting in the icy fjord of the back-of-house freezers. I feel like God, a mighty creator, looking down on my disciples,” my coworker Simone reflects on the process.

Yet the choctoppers work is never done; the process is crushingly sisyphean. An entire day’s worth of choctops can disappear in a matter of hours, thanks to several sessions full of septuagenarians on a Saturday.

The choctop shift can be tranquil, humbling, and quietly frustrating. Good conversation and a bluetooth speaker makes them that much better, but the cycle is destined to repeat itself.

Photographer: Patrick McKenzie

Assist: Luca Cruzado

Choctoppers: Patrick McKenzie, Alice Kotowicz, and Genevieve Ripard

Flavours: Vanilla, Caramel Honey Macadamia, Cookies and Cream, Mint and Cookies